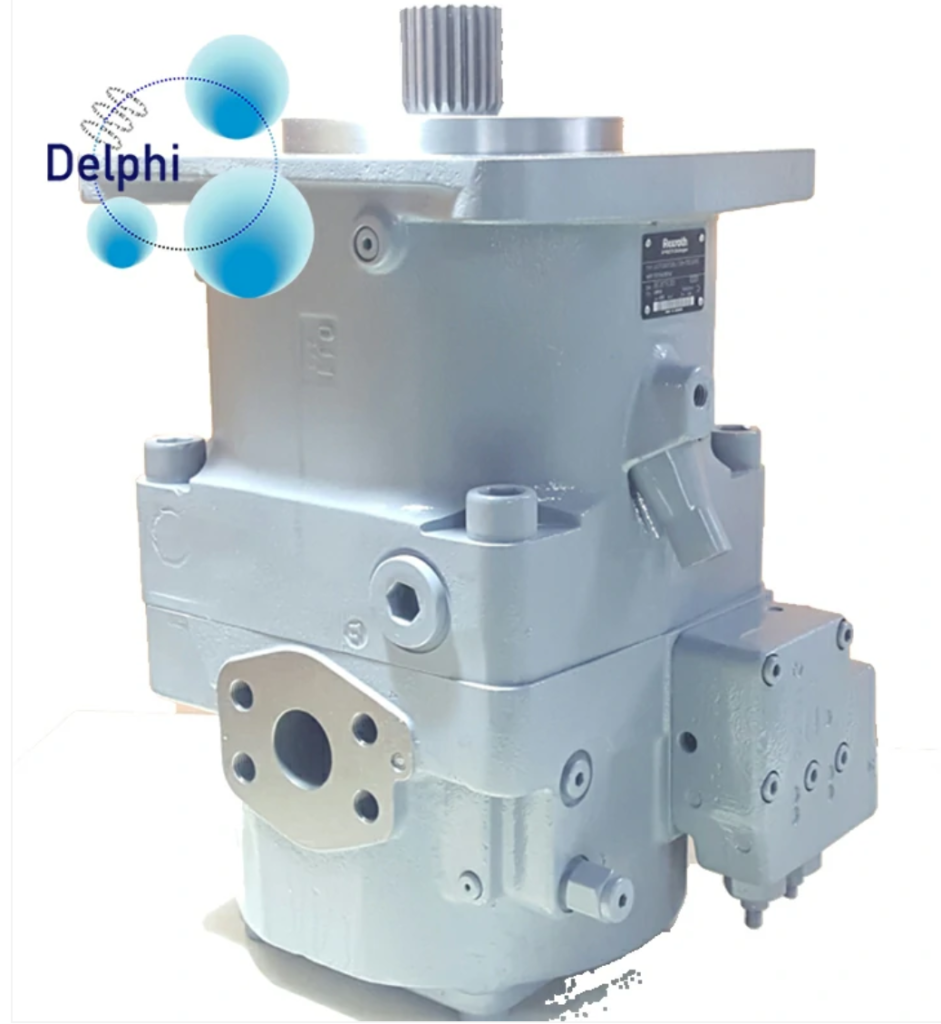

Axial piston pumps are a type of positive displacement pump commonly used in hydraulic systems.

The basic working principle of an axial piston pump is as follows:

- Swash plate design:

- The pump consists of a rotating cylinder block with multiple pistons arranged in an axial configuration.

- The pistons are in contact with a swash plate,cara kerja axial piston pump which is inclined at an angle relative to the axis of the rotating cylinder block.

2. Suction and discharge:

- As the cylinder block rotates, the pistons move in and out of the cylinder bores.

- During the suction stroke, the pistons move away from the swash plate, creating a vacuum that draws fluid into the cylinder bores.

- During the discharge stroke, the pistons move towards the swash plate, pressurizing the fluid and pushing it out of the cylinder bores.

3. Fluid flow:

- The angled swash plate causes the pistons to move in a reciprocating motion as the cylinder block rotates.

- This reciprocating motion of the pistons creates a continuous flow of fluid through the pump.

4. Pressure generation:

- The pressure of the fluid is generated by the force applied to the pistons as they are pushed against the swash plate.

- The amount of pressure generated depends on the angle of the swash plate and the speed of the pump.

5. Fluid control:

- The flow rate of the pump can be controlled by adjusting the angle of the swash plate.

- Increasing the angle of the swash plate increases the stroke length of the pistons, resulting in a higher flow rate.

- Decreasing the angle of the swash plate reduces the stroke length and the flow rate.

Axial piston pumps are known for their high efficiency, hydraulic axial piston pump compact size, and ability to handle high pressures. They are widely used in various industrial applications, such as construction equipment, agricultural machinery, and hydraulic systems.