PPGI (Pre-Painted Galvanized Iron) interacts with insulation materials in several ways:

1. Thermal Performance

- Reflectivity: PPGI can reflect sunlight, reducing heat absorption. When combined with insulation materials, this can improve overall thermal efficiency.

- Insulation Layering: Adding insulation beneath or alongside PPGI can enhance energy efficiency by minimizing heat transfer.

2. Moisture Resistance

- PPGI provides a protective barrier against moisture, which can be beneficial when used with insulation materials. ppgi factory Properly installed, it helps prevent moisture from reaching insulation, reducing the risk of mold and degradation.

3. Compatibility

- Different insulation materials (e.g., fiberglass, foam) may have varying compatibility with PPGI. It’s essential to ensure that any adhesives or fasteners used do not react negatively with the metal coating.

4. Structural Support

- PPGI can provide structural integrity for insulation systems, especially in roofing and wall applications. It helps maintain the shape and effectiveness of the insulation.

5. Fire Resistance

- Depending on the type of insulation used, the combination with PPGI can either enhance or compromise fire resistance. It’s crucial to select materials that meet fire safety standards.

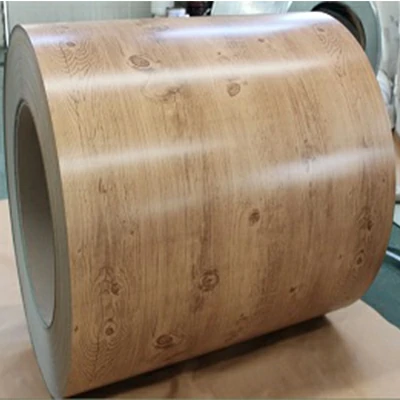

6. Aesthetic Appeal

- PPGI comes in various colors and finishes, allowing for a visually appealing exterior while providing insulation benefits.

Conclusion

When integrating PPGI with insulation materials, it’s important to consider factors such as thermal efficiency, moisture resistance, compatibility, and fire safety to ensure optimal performance and longevity.