Black pipe fittings are a type of pipe fitting that are made from black iron or steel. They are commonly used in plumbing and gas distribution systems, as well as in industrial and commercial applications.

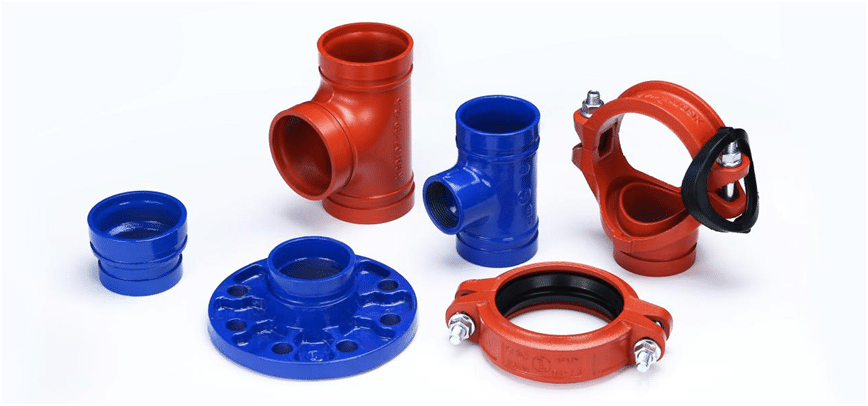

Black pipe fittings come in a variety of shapes and sizes, including elbows, tees, couplings, unions, and nipples. They are typically threaded on both ends, which allows them to be easily connected to other pipes or fittings using pipe wrenches or other tools.

One of the advantages of using black pipe fittings is that they are highly durable and can withstand high pressure and temperatures. They are also resistant to corrosion and can be used in a variety of environments and applications.

However, black pipe fittings are not recommended for use in potable water systems, as they can leach chemicals into the water and may not meet certain regulatory standards. In addition, they may require more frequent maintenance and inspection to ensure that they are in good working condition.

When selecting black pipe fittings for your application, it’s important to choose fittings that are compatible with the type of pipe and system you are using, and to follow all relevant safety and installation guidelines. You may also want to consult with a professional plumber or contractor to ensure that you choose the right fittings for your specific needs.

When it comes to potable water systems, there are several alternatives to black pipe fittings that may be more suitable. Here are some examples:

Copper Fittings: Copper fittings are a popular alternative to black pipe fittings for potable water systems. They are durable, corrosion-resistant, and can be easily installed using soldering techniques. Copper fittings are also compatible with a wide range of pipe materials and can be used in both residential and commercial applications.

PEX Fittings: PEX (cross-linked polyethylene) fittings are another alternative to black pipe fittings for potable water systems. china pipe PEX fittings are lightweight, flexible, and easy to install using crimp or clamp connections. They are also resistant to corrosion and can be used in a variety of plumbing applications.

PVC Fittings: PVC (polyvinyl chloride) fittings are commonly used in potable water systems, particularly in residential applications. They are lightweight, durable, and easy to install using solvent cement. PVC fittings are also resistant to corrosion and can be used in a variety of plumbing applications.

Stainless Steel Fittings: Stainless steel fittings are a high-quality alternative to black pipe fittings for potable water systems. They are durable, corrosion-resistant, and can be used in high-temperature and high-pressure applications. Stainless steel fittings are also compatible with a wide range of pipe materials and can be used in both residential and commercial applications.

When choosing an alternative to black pipe fittings for your potable water system, it’s important to consider factors such as compatibility, durability, and safety. You may also want to consult with a professional plumber or contractor to ensure that you choose the right fittings for your specific needs.