Framing nails can perform differently in hardwoods compared to softwoods due to variations in the density, grain structure, and hardness of the wood species.

Here’s how their performance may differ:

- Penetration: Hardwoods, such as oak or maple, typically have denser and harder fibers compared to softwoods like pine or cedar. As a result, framing nails may penetrate softwoods more easily and with less resistance than hardwoods, where they may require more force to drive into the material.

- Holding Power: While framing nails may penetrate softwoods more easily, they may also provide less holding power compared to hardwoods. Hardwoods have a tendency to grip nails more tightly due to their dense and hard fibers, resulting in better resistance to withdrawal forces and improved overall holding power.

- Splitting: Hardwoods are more prone to splitting than softwoods due to their density and hardness. Improperly driven nails or nails with inadequate holding power may cause hardwoods to split, especially near the edges or ends of the boards. Pre-drilling pilot holes or using specialized fasteners like ring shank nails can help minimize splitting in hardwoods.

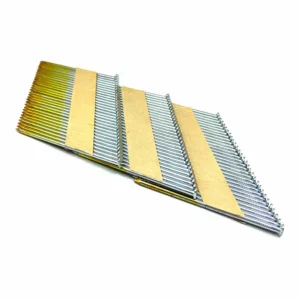

- Wear on Nails: Driving nails into hardwoods can cause more wear and tear on the nails compared to softwoods. framing nails The harder fibers of hardwoods may exert greater stress on the nail shaft, leading to increased bending, deformation, or breakage of the nails, especially if they’re not properly sized or made from high-strength materials.

- Resistance to Withdrawal: Framing nails driven into hardwoods generally provide better resistance to withdrawal forces compared to softwoods. The dense and hard fibers of hardwoods create a tighter grip on the nails, reducing the risk of the nails pulling out under load and improving the overall structural integrity of the fastening.

Overall, while framing nails can be used in both hardwoods and softwoods, their performance may vary based on factors such as penetration, holding power, splitting, wear on nails, and resistance to withdrawal. It’s essential to consider the specific characteristics of the wood species and select appropriate fasteners and installation techniques to ensure secure and durable fastening in both hardwood and softwood applications.